To introduce my self, I am a mechanical engineer from Amsterdam.

In my profession, I make technical drawings, 2d and 3d.

I have experience with multiple cad programs, both 2d and 3d.

I also once build maps for a game, Aliens vs Predator 2.

After watching some tutorial vids of blender I get confused.

Nobody in blender seems to care about the actual size of things ?

I also watched a vid of a guy making a coffee cup.

I totally don’t understand why he does not draw a cross section of that cup, and then use a commando like revolve, to make the 2d sketch a 3D object. ( he does this to make the handle of the cup, he send a circle along a path )

Then his way of connecting that handle to the cup.

Is that really the right way to do it in blender?

In a cad program I would have used a boolean operation, which I already have seen in blender.

From reading online I think I do understand that blender does not use what cad program calls solids.

I think I also understand why, nobody with blender is interested in stress calculations, so solids are overkill for a program like blender.

But did I pick the wrong tutorial (s) or, do I need to learn a new way of thinking and 3d modeling.

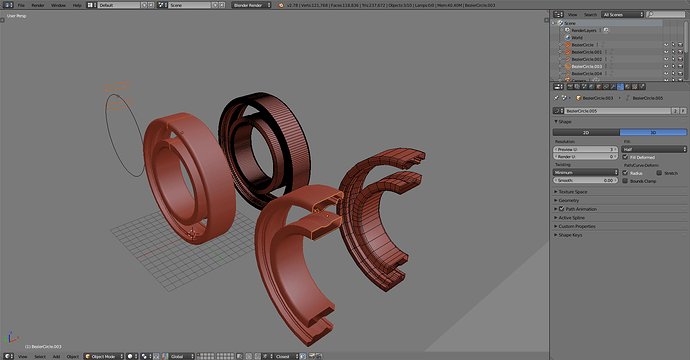

The drum in the Catia picture, can this be done in Blender with using actual dimensions ?

Like the drum is 2000 mm ( round ) and a height of 2000 mm, and the the cut out groove 20 mm in height ?

To end this positively. I tried blender before, and gave up rather soon, because that interface drove me mad.

My first impression of the newer blender is much better.

I installed blender on opensuse leap 42.2. (linux)