Hello awesome blenderfam!

This is gonna be my first post in a forum I have been following for a while, I’m pretty stoked about this. This might not be the right place to post this but I hope I can at least find some direction from here. Your help is greatly appreciated.

So, just a little background:

I have been using blender for simple 3D rendering and modeling for quite some time now:

https://www.instagram.com/p/BezWWQ3hUEX/?utm_source=ig_web_copy_link

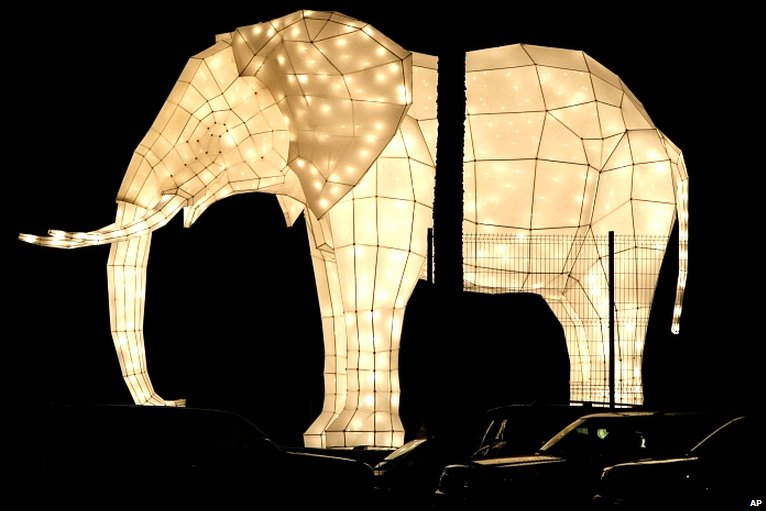

, honestly it’s the best program out there IMO. And it’s because of you guys! The community aspect of it beats all other competitors. Earlier this year, I started collaborating with a friend of mine who needed renders made for his sculptures. He’s made things for burning man, Chicago parks district, etc.

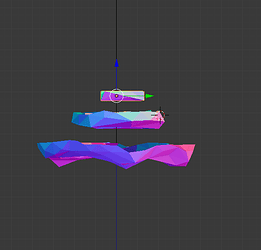

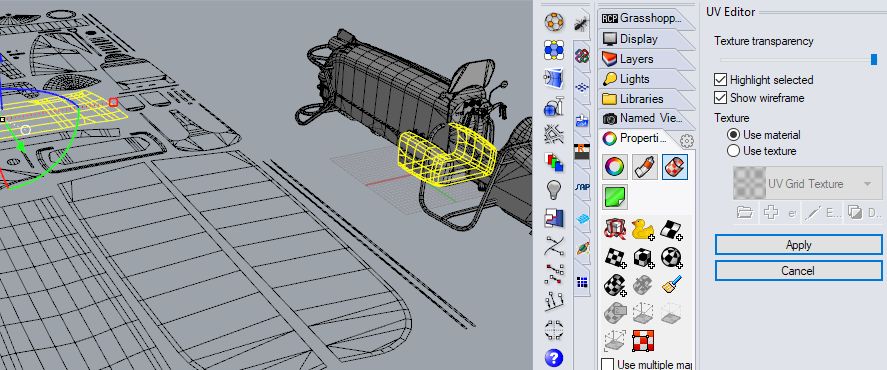

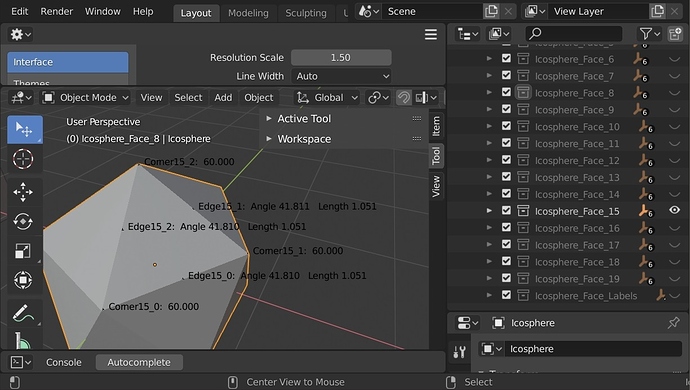

We started working on some renders for proposals and after sometime I found myself at his studio constantly, now helping him design the fabrication and engineering aspect of his sculptures (I will attach some pics for reference). I have been mainly using blender to sculpt polygon based topographies, and haphazardly understand them in terms of geometry and fabrication. So far it’s been good as it fits his aesthetic. But now I have reached a MAJOR roadblock: going from design/render to actual sculputure.

I have had good luck figuring this out by myself, but I really need your help now, with any ideas that you may have of where to go, who to ask, and what are the right questions to ask, or programs that I could fit into my workflow, tips, a thing helps.

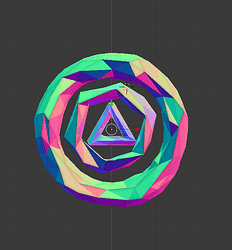

This is what we’re trying to make a reality:

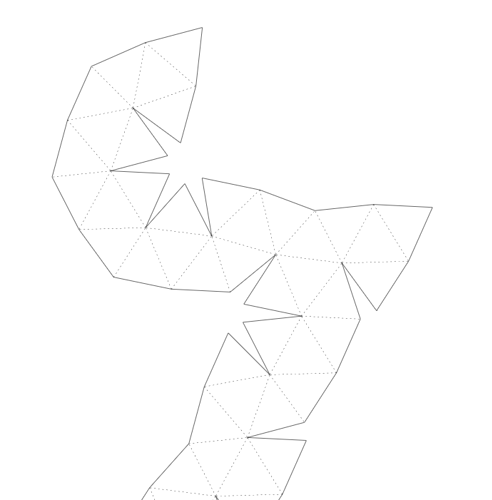

What you see here are three concentric rings where each one has a higher level of complexity than the one before, the first object having 75 tri’s, the second 150, and the third 357. Were using dichroic acrylic as it’s the material of choice for my friends work. He’s had a lot of experience with building low poly structures (but never ones that are as irregular as this). The planes are attached to each other by brackets, or a frame, or (suggestions?) and then are hung with aircraft cable to the ceiling.

I started by thinking about how to unpack the mesh into a pattern that could be laser cut out of acrylic. That process was pretty straightforward, as this is pretty standard for low poly paper modeling, which I have no experience with but has been my northern star for all of this. Blender had some options, but pepakura really gave me what I have needed (so far). for those of you that dont know it, its a great piece of software that turns 3d objects into foldable paper models.

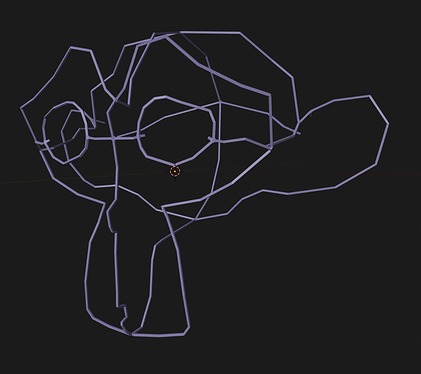

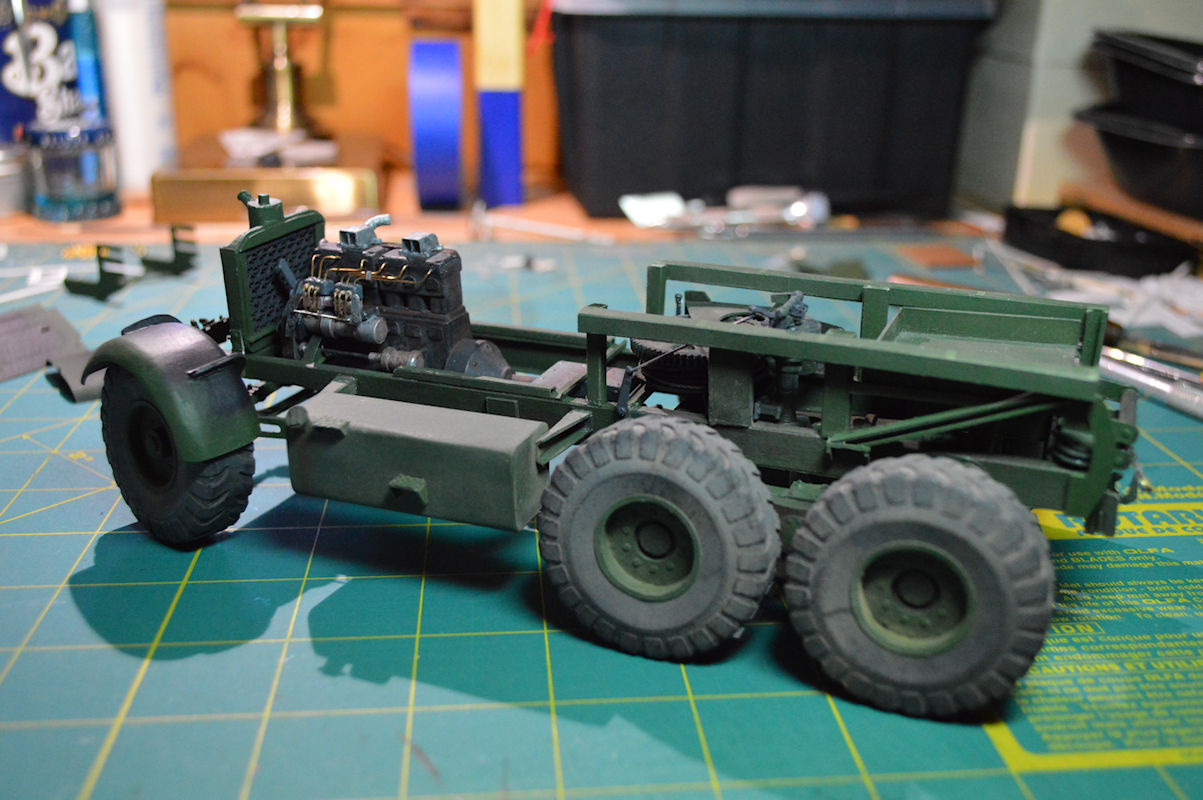

I took the topmost piece in the sculpture and brought it into pepakura to make this cardboard model:

This was somewhat of a complicated process as there are material dimensions that need to be taken into consideration when two faces meet at a certain angle (particularly really Acute ones), but this was a pretty good way to understand the shape in space. The hardest part was going from an unfolded shape to a folded one, as it was really confusing and hard to keep all of the faces together with the tape. We thought a frame would help best in attaching the faces, and it gives us flexibility if we were to Tessa late or break faces. But I’m resching a real mental block when thinking about how we would get to building a frame, how to manufacture that, how to figure out all of the angles between faces, automating that process etc. Seems like blender might not be the right choice, but I must be missing something. I will update and edit this thread as the project develops but welcome to my personal little heaven and hell! Hope you enjoy it and thank you for your contributions.