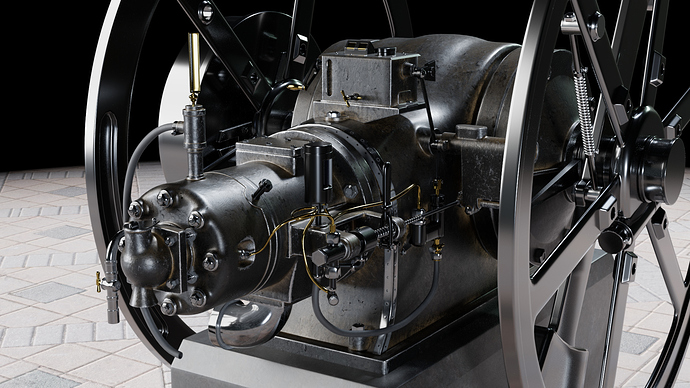

Will you make it rusty?

I’ve tried out multiple materials and it seems that giving it a complicated material will give it so much extra detail that the whole render looks like a mess so I have to go with subtlety.

Unfortunately SubstancePainter keeps crushing even after the recommended registry setup and I’am starting to loose my cool!

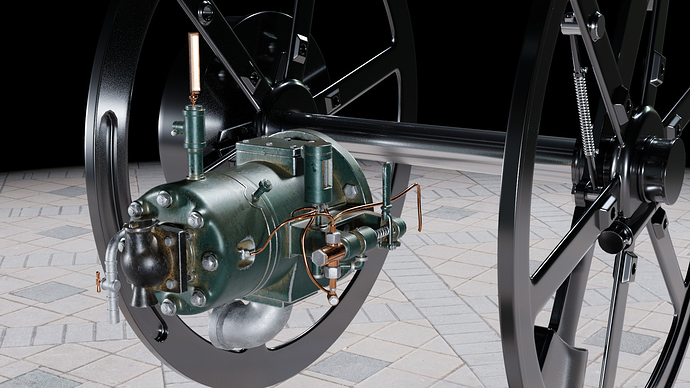

Massive improvement over last render.

I had to export the engine in smaller meshes to SP since it couldn’t handle large polycount objects on my machine and it crushes all the time. This led to some tedious work, but so far it seems it worth the effort.

The biggest objection that I would have is that an actual engine would never be made of “brightly shiny metal.” Virtually all of it would be painted, and they used standard color schemes which can be researched on almost any web-site devoted to agricultural-machinery (or, oil-drilling machinery) aficianados. You should give your model a realistic and historically-accurate paint job everywhere.

The metal would have been cast, and machined on some surfaces such as the rim of the wheels or the cylinder area, but many of the surfaces would be rough. (They would have been high-quality castings, of course, but sand-castings nonetheless, and they would look the part.) When they left the factory, they had a spit-shine look to them (as any manufacturer would do), but that look didn’t last long in the field. Mostly they were painted to be weatherproof.

Nice engine, and very realistic paintjob too. I am not sure if I would go for black though.

Since the wheel outside the flywheels was normally used to drive a so-called line shaft, with one or more devices attached to it, it was usually more than a foot wide.

Henry Ford accumulated a collection of hundreds of machines of all types, including many oil engines, and although the Ford Museum collections have since been fairly sacrificed upon the modern-day altar of “relevance,” they continue to have many archives. The author of the web-page that you cite must surely have access to blueprints and instruction manuals which (s)he could share.

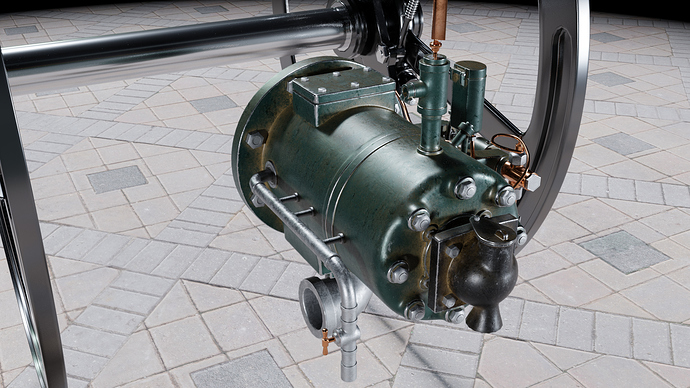

Apparently-trivial details would matter to an engine-buff. For example, on the reference photo you will notice the square bulges on the various arms of the wheel. These weren’t decorative and they weren’t counter-weights: they were sprue-holes from the casting process, needed to ensure that hot metal reached equally into various parts of the mold. They were cleaned-up but not machined away. The ends of the spokes flare out to the wheel for the same reasons. The front of the engine body is rounded because that’s easier and more reliable to pour. A metal tire is apparently shrink-fitted to the outside of the flywheel. The four holes drilled into the inside of the flywheel likely were balancing adjustments. The flywheel was pressure-fitted to a keyed shaft and secured with the visible key.

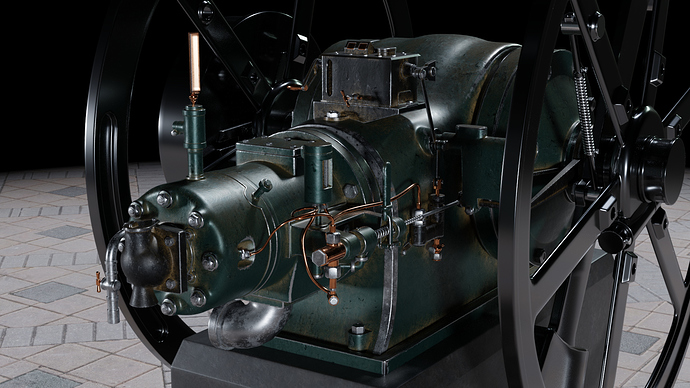

you are on the right way.the materials with the dirt and rust, are clealy a improvement.

one thing i noticed is your lighting.look at your upper 25% from your render.the wheels are almost black,and vanishing into the black backround.you can use a additional rim light,if you want to keep your actual lighting,to give the wheels his siluette back.

i would try a different backround,or HDRi to make this great model to a even better or interesting render.

While I am in no way qualified to comment on the graphics aspect of your superb model, as a retired engineer I am astounded at how realistic your engine appears.

I see you have added a toggle link at the bottom of the fuel injector priming lever and you may be interested to see an excellent description of this very engine here https://www.old-engine.com/fm15yh.htm

Sincere congratulations for showing what can be achieved.

Very nice model and materials are beginning to look the part, however, I echo the comments of my friend @sundialsvc4, you need to get the cast elements looking like painted castings, not vacuum moulded plastic. As he says, only certain faces, like where bolts go, would be machined and they will show milling, or other tool marks. These you can do easily with a bump map. If you are stuck with any of the rigging, just ask, I have done a lot of this type of rigging.

Keep up the good work.

Cheers, Clock.