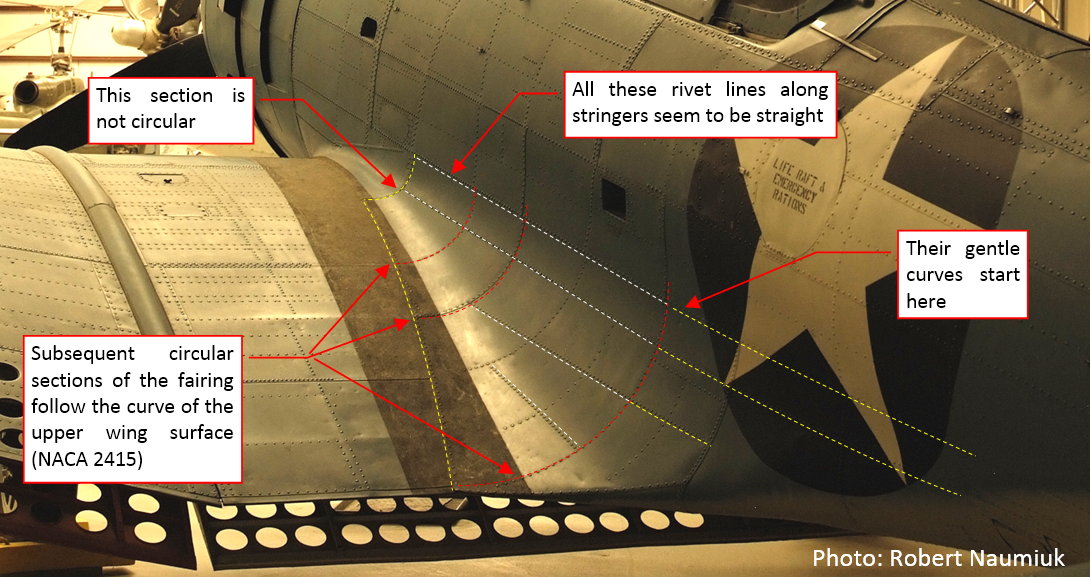

Thank you, smith123! Precisely - when I am making such an aircraft model like this, I always analyze its details, learning what the designer wanted to achieve. (Looking for solutions of the typical engineering cases, technology used for their solution, and the other elements).

In this post I will finish the “general modeling” phase of the wing, recreating the last missing elements. Of course, the result presented in this section is not the “final product”. It is just detailed enough for the next phase — applying textures and materials. (I will do it when I form the whole model). After applying the textures I will come back to this wing during the detailing phase, and recreate all its small details (like various small openings, aileron hinges, running lights, landing light, etc.).

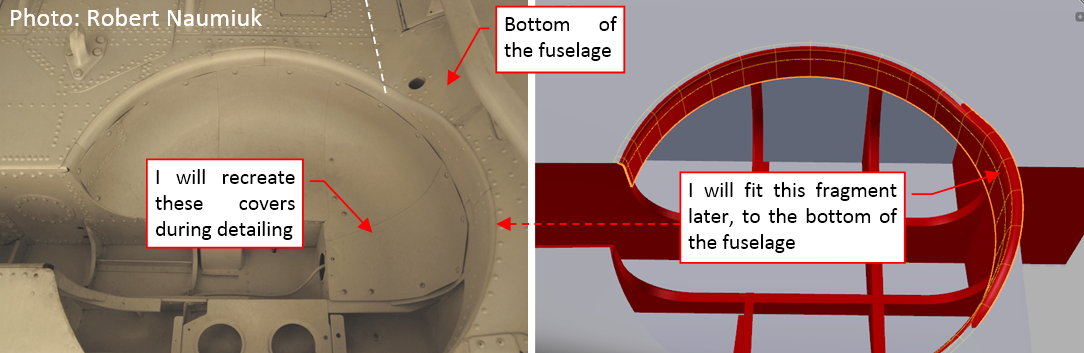

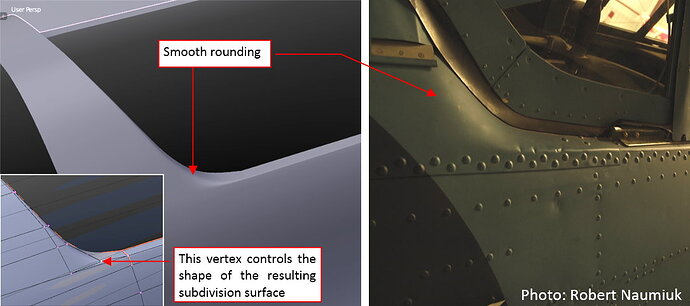

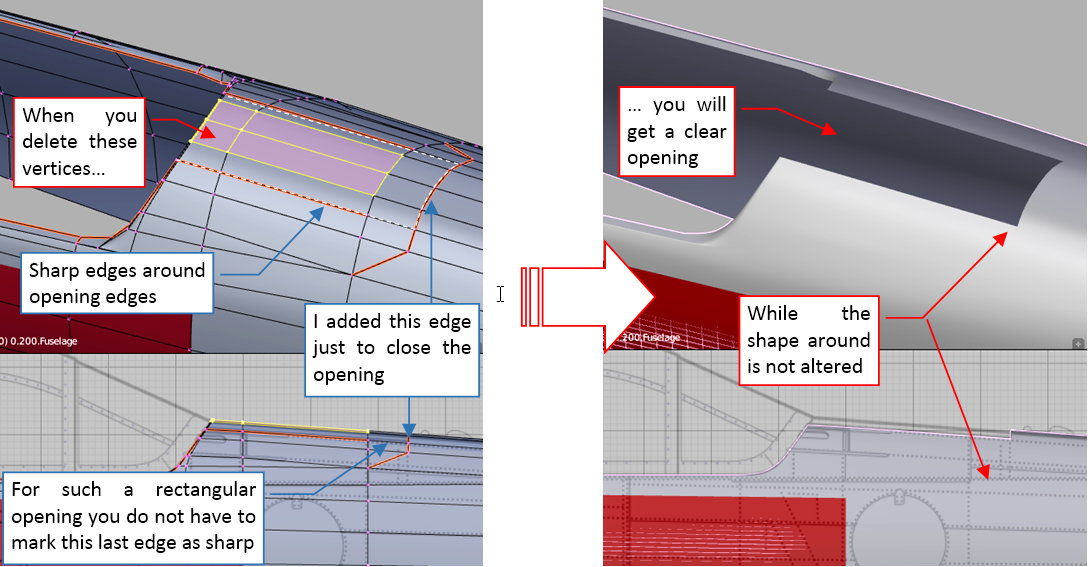

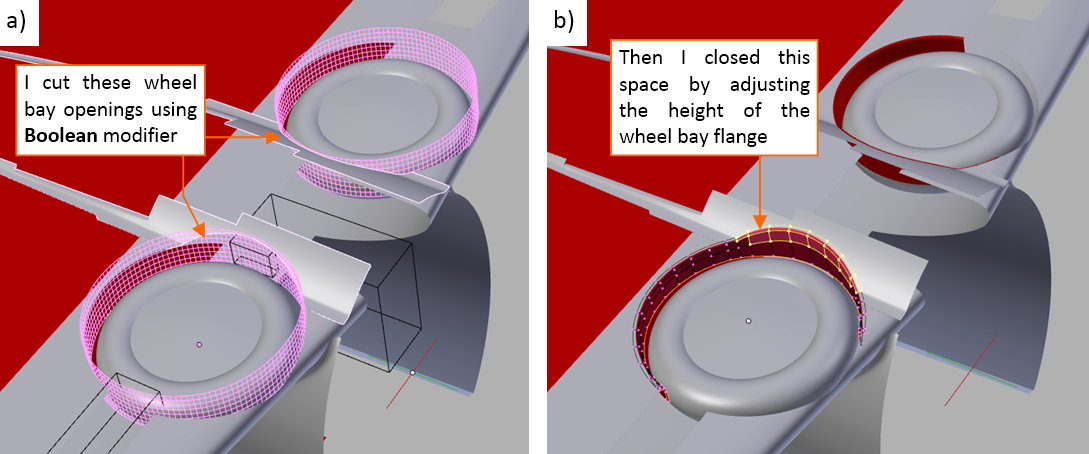

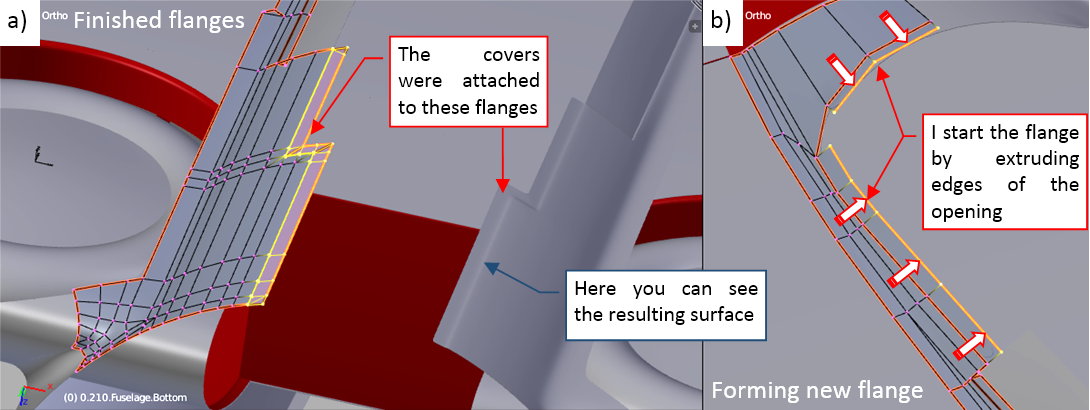

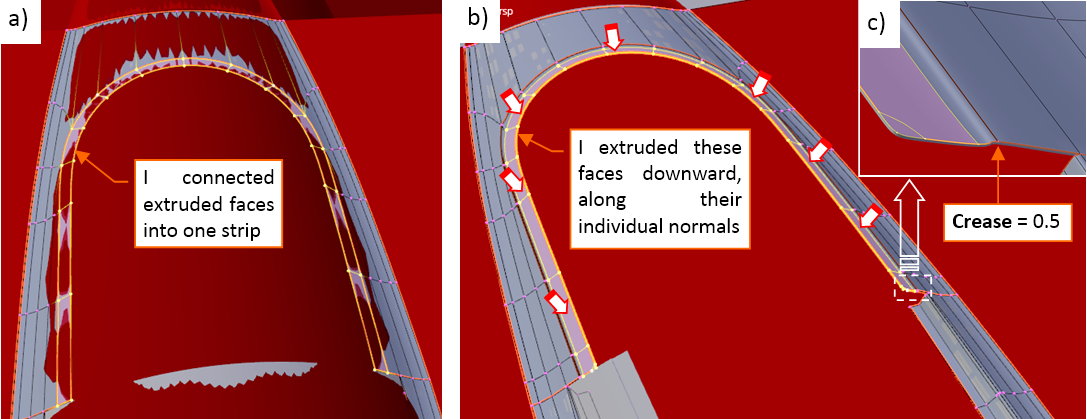

Finishing the wheel bay, I decided to add the rounded flange around its edges:

I just did it because I do not like to see a non-realistic, “suspended in the air” edge of an opening. A part of this flange has to fit into the bottom of the fuselage. At this moment I left on that flange an “informal”, elevated fragment. I will fit it to the fuselage when it will be ready.

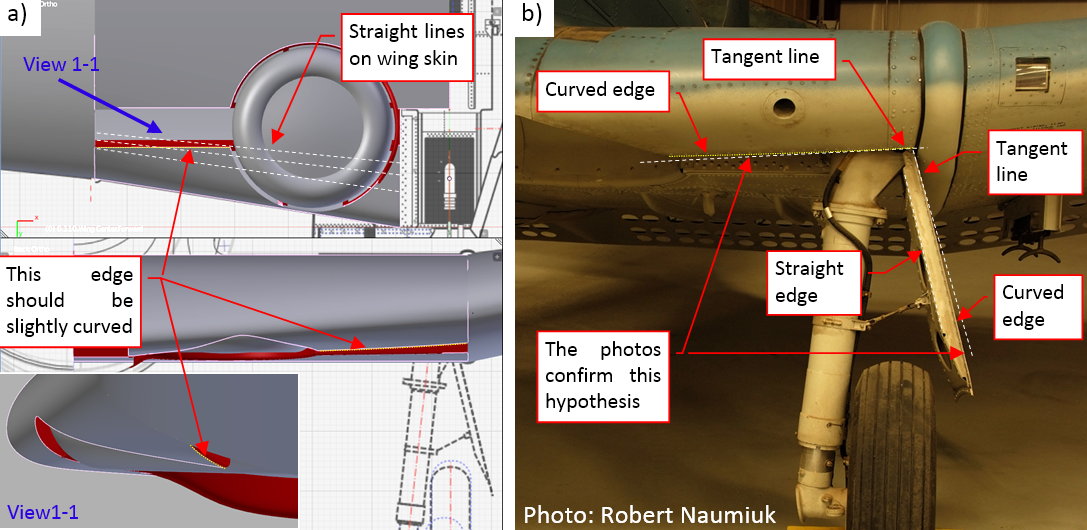

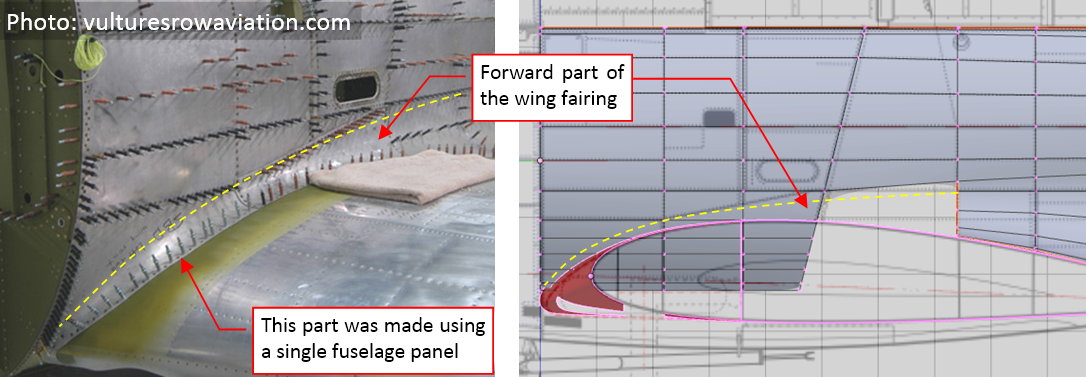

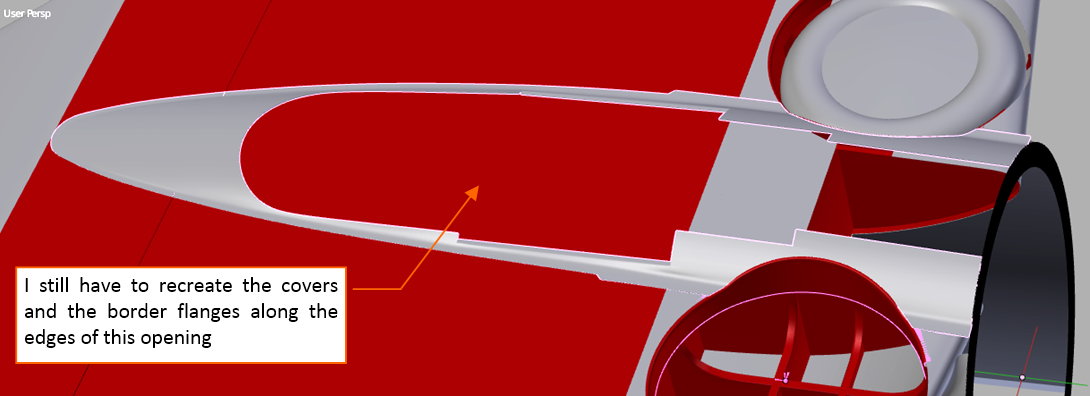

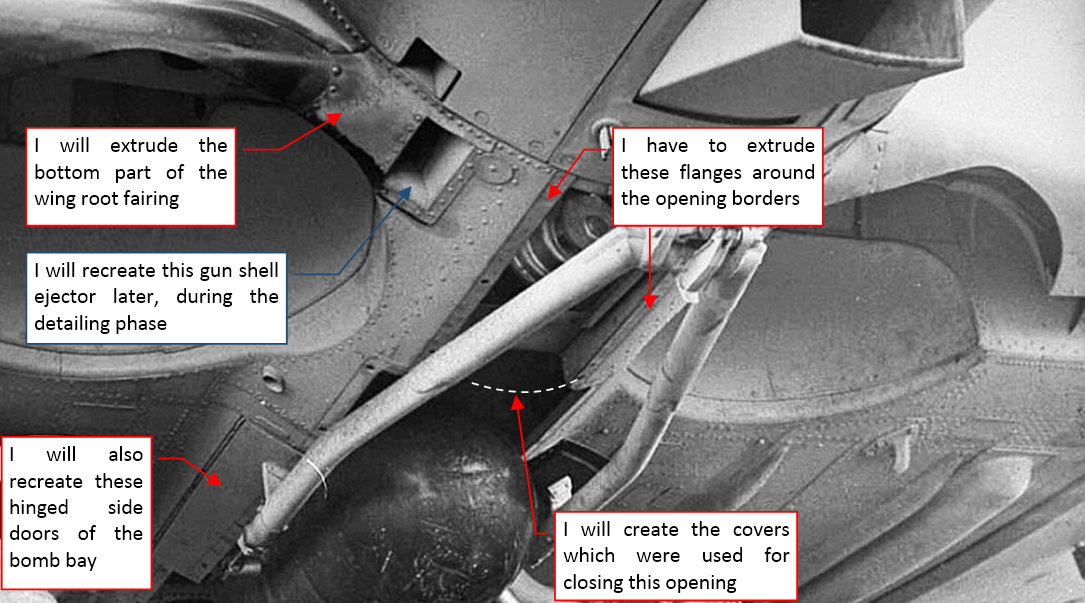

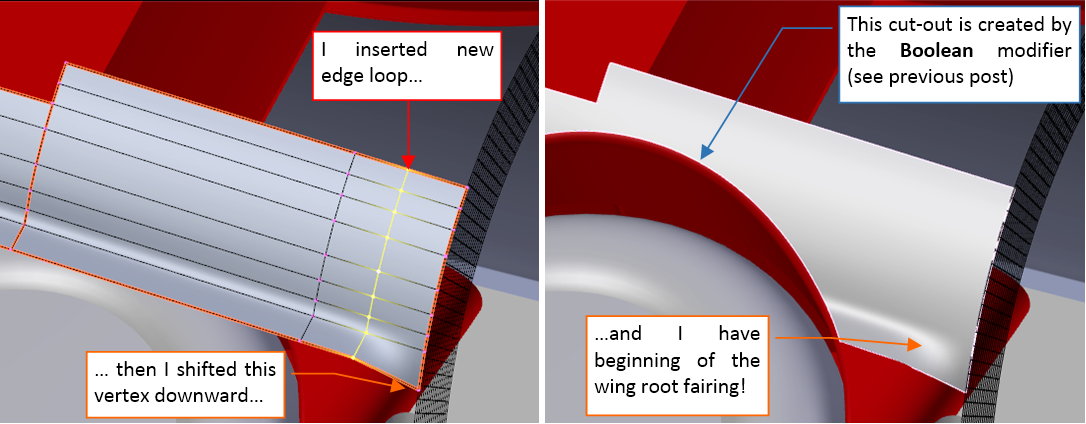

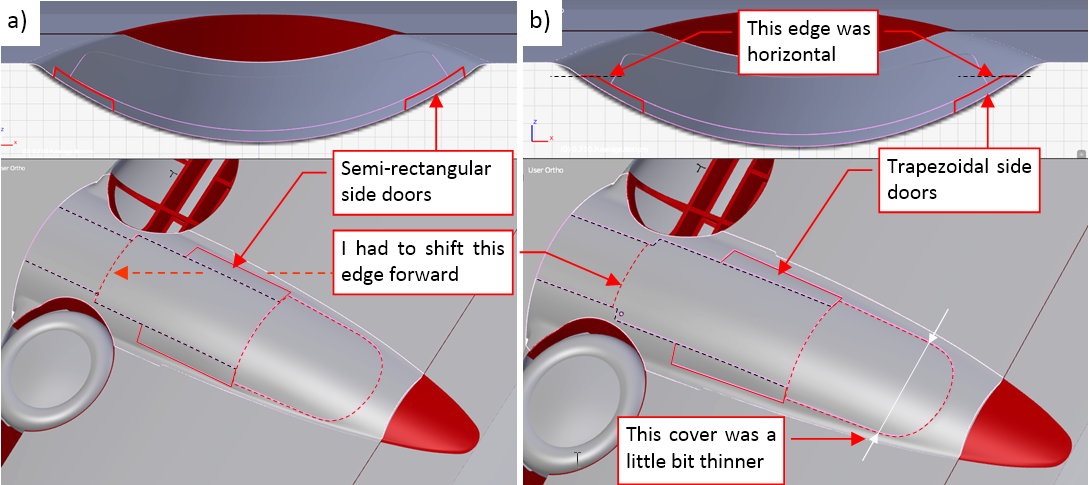

There is another detail which is too subtle to be found on any scale plans. It is the shape of the landing gear leg bay, speaking more precisely —of its front edge:

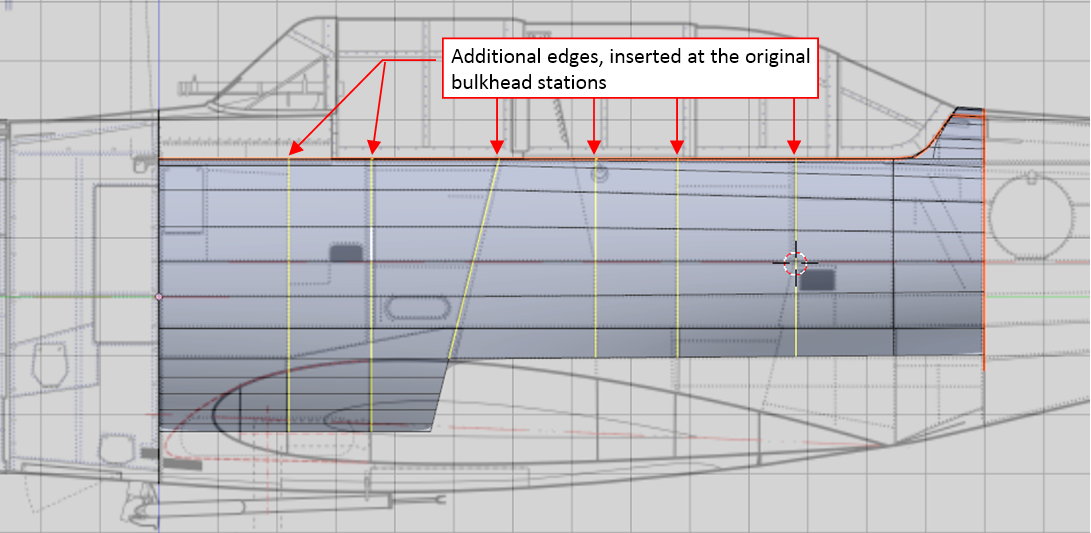

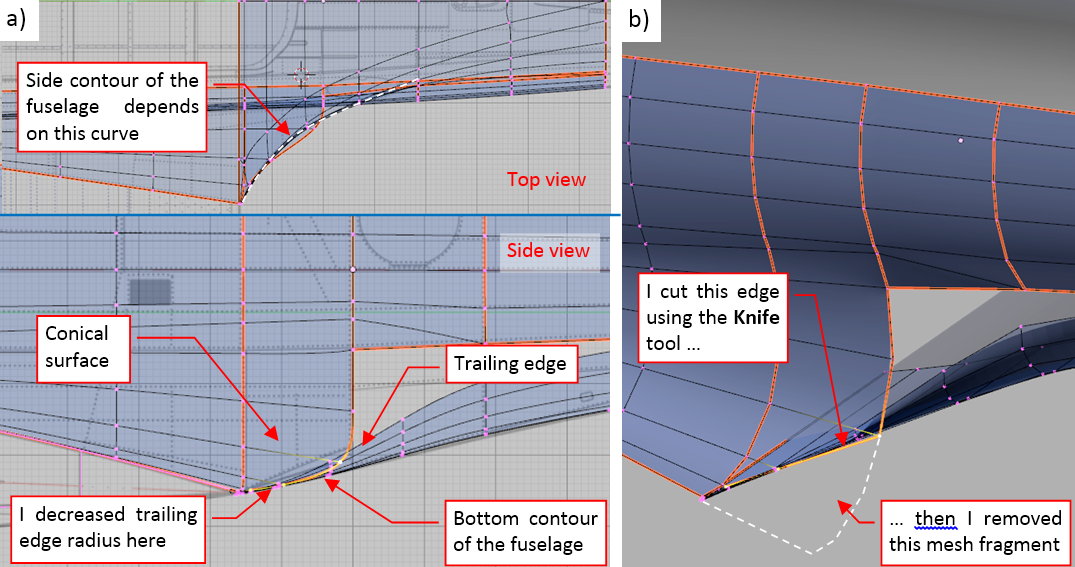

In the top view the front edge of this opening is a straight line, perpendicular to the aircraft centerline. Such an edge goes across several theoretical straight lines that you could draw on the bottom wing surface (see picture “a”, above). This means that in the front view this edge forms a gentle curve.

Initially I did not know if the Dauntless designers reproduced such a geometrically correct, but technologically more difficult shape. (Such a curved shape is more expensive because it requires additional formers for the wing skin panels and landing gear cover). I could imagine the situation when they decide to simplify this edge to a straight line. Fortunately, I have many high-resolution pictures of various restored SBDs. Photos of the landing gear confirm that this edge was curved (see picture “b”, above).

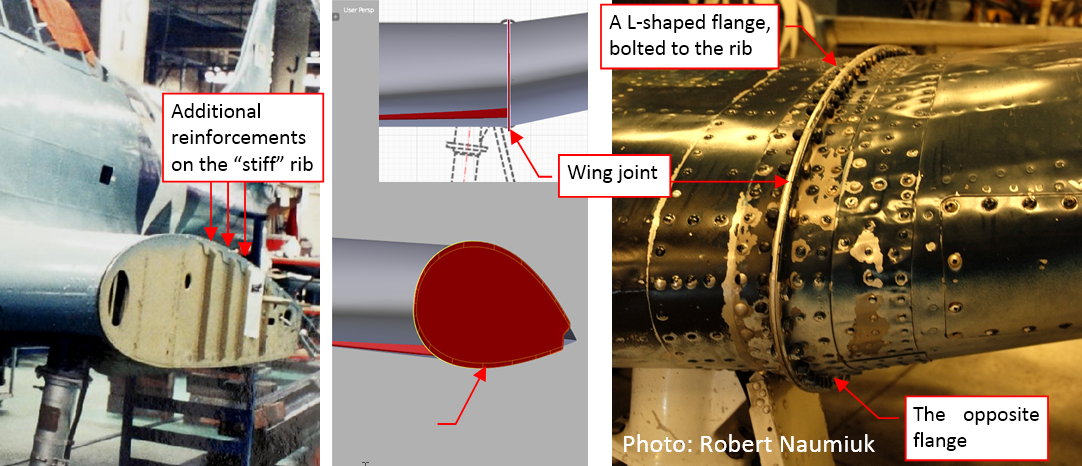

Another element I added was the solid rib that closes the center wing section. It is a standard Northrop solution for joining multicellular stressed-skin wing, designed in 1930 for their Alpha aircraft. Both wings were joined by multiple bolts evenly distributed around the airfoil circumference. The forces from the bolts were transferred to the wing skin via “L”-shaped flanges. You need to place a stiff rib between such flanges, because otherwise the whole structure would collapse. That’s why the rib closing the wing section is a solid, thick aluminum plate:

I am not sure if I estimated properly the thickness of this rib. Anyway, I did it using a Solidify modifier, so it will be easy to alter this setting later. Because of this unusual thickness I am not sure if I will recreate the openings in this element (you can see them on the photo) using textures. The alternative method is to modify this mesh (it should be not very complicated, because it is a flat plate). During the detailing phase I will also recreate the vertical reinforcements visible on the photo.

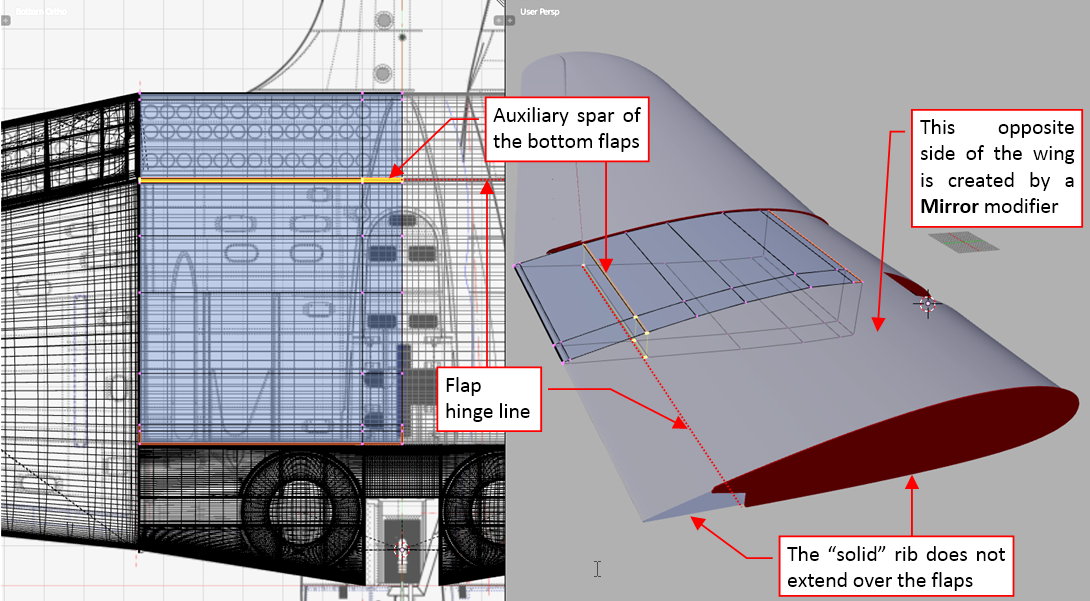

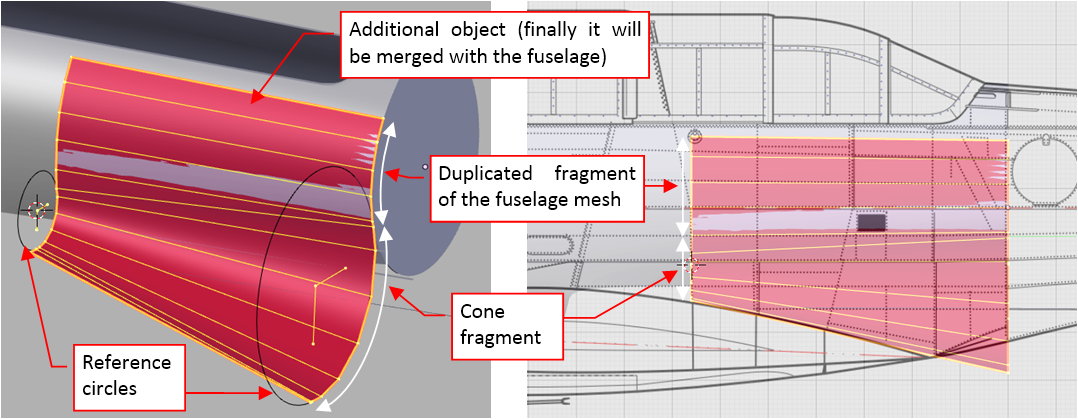

I started the bottom flap of the center wing section by preparing the auxiliary spar running along the flap hinges:

As you can see, I also created the symmetric, right side of this wing section, using a Mirror modifier.

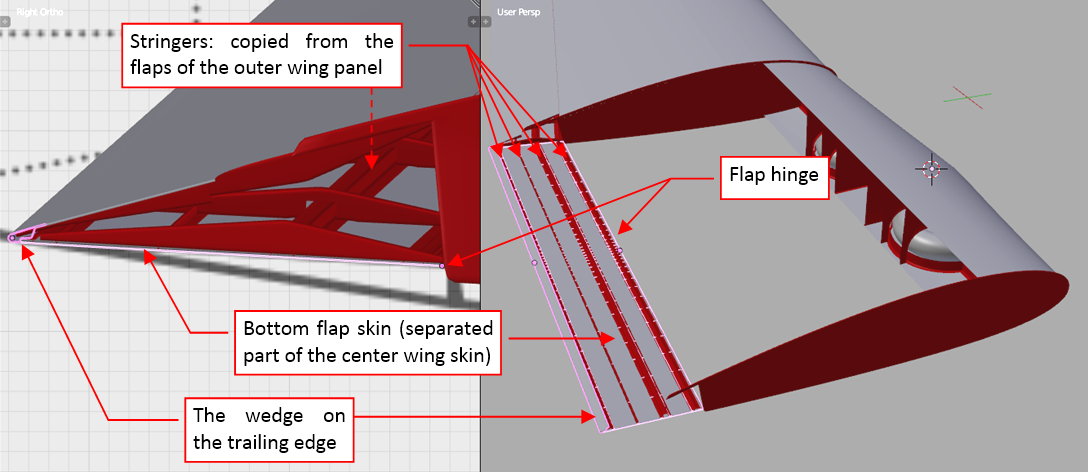

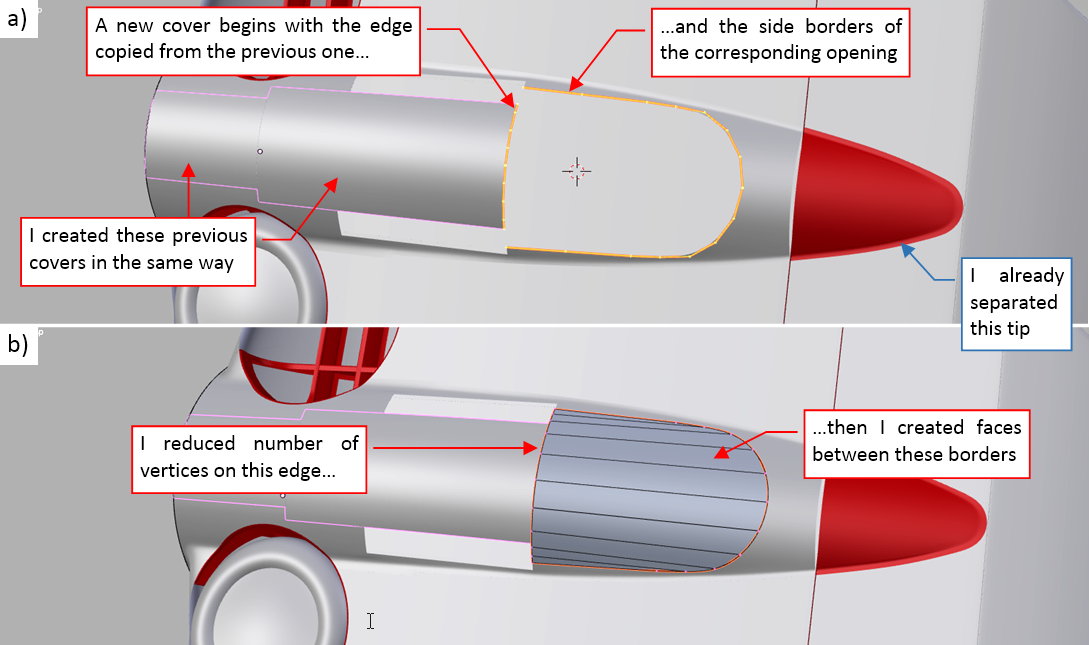

The flap is created in the same way as the flaps of the outer wing panel. I separated the bottom part of the wing trailing edge into the flap skin. I added a very long, thin cylinder as the flap hinges. I copied the trailing wedge from the outer wing panel and placed it on the trailing edge:

Then I copied the flap stringers from the outer flaps. In fact, I used just the cross sections of these original objects, extruding them into new stringers. I used Mirror modifiers to create the opposite sides of all of these spanwise flap reinforcements.

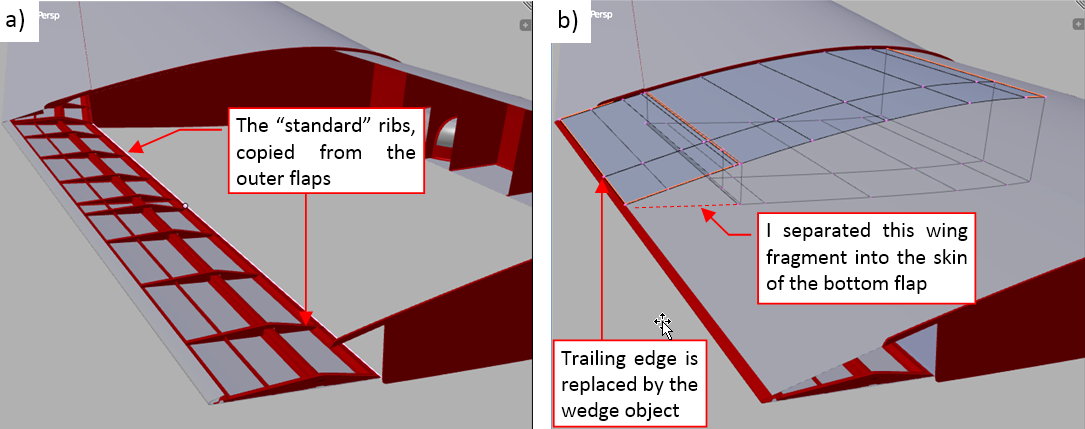

In the next step I copied from the outer flaps the “standard” flap ribs (they all are clones that share the same mesh - see picture “a”, below):

Finally I modified the upper part of the center wing mesh, integrating it with the trailing wedge (see picture “b”, above).

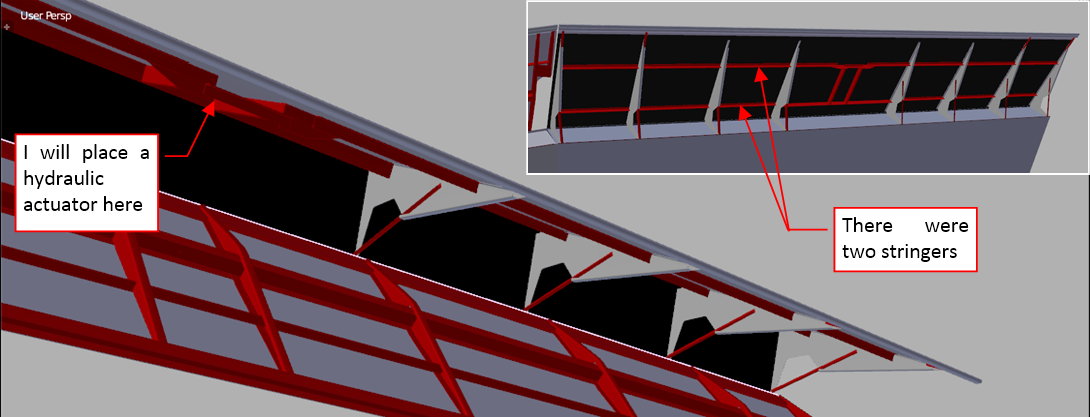

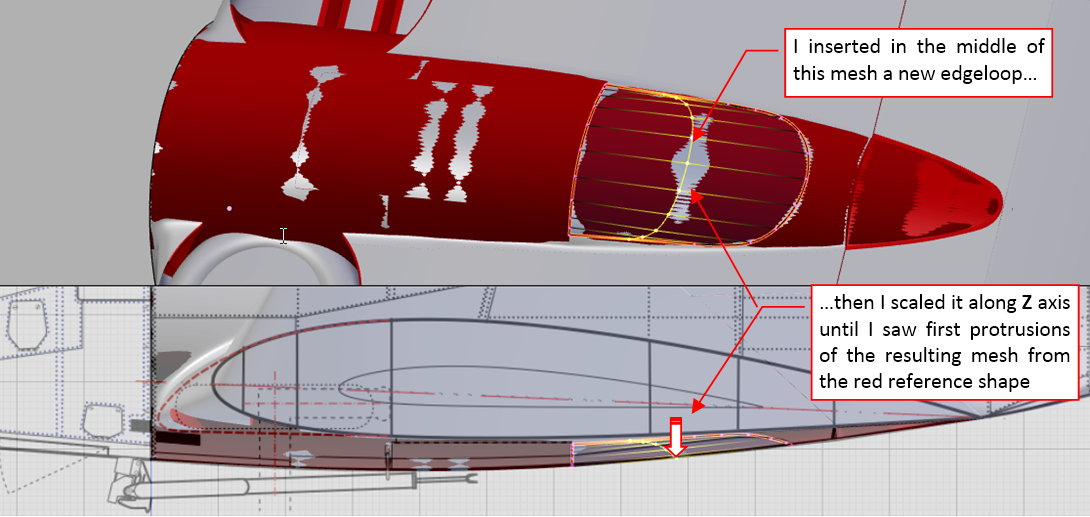

When you open the split flap, you can see the internal structure of the wing:

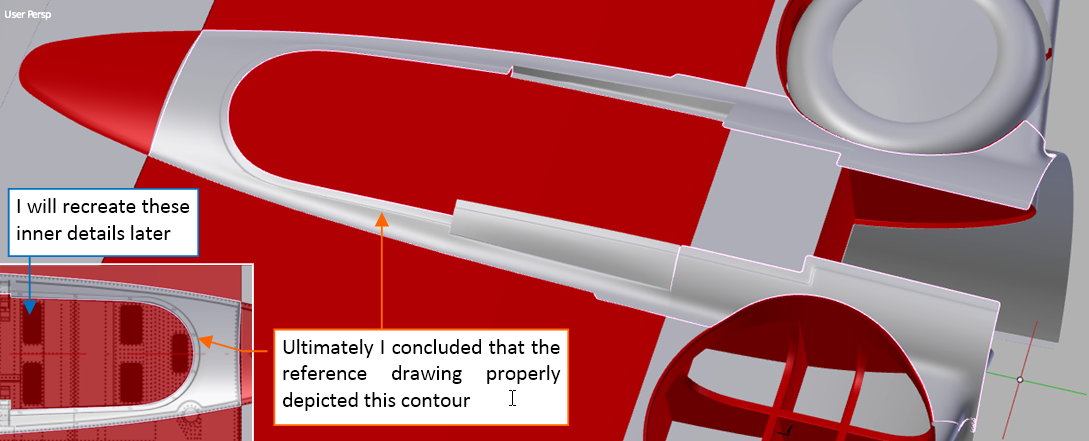

I studied the available photos of the flap bay in the center wing, then recreated the key ribs and spars:

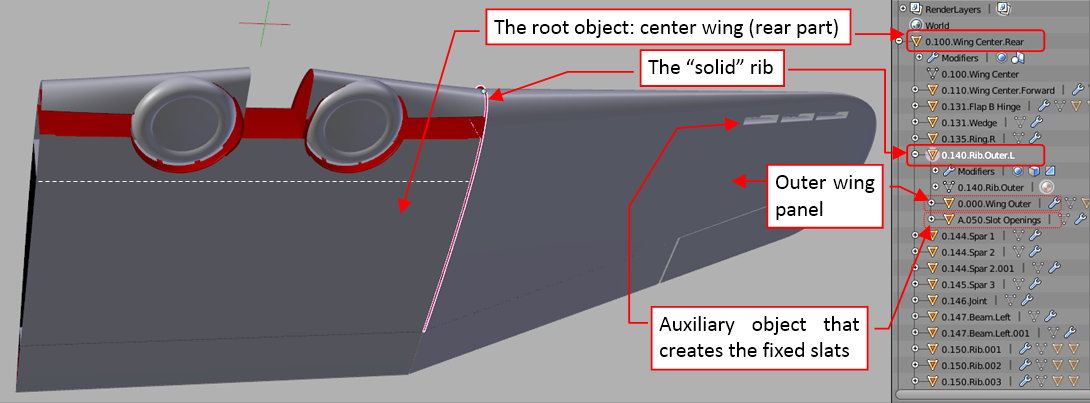

Finally I organized the whole wing into the appropriate hierarchy. At this moment the root element is the wing center — more precisely, its rear part:

I placed all external wing elements on layer 1, while all internal parts are on layer 11. The auxiliary “cutting tools” used in the Boolean modifiers are in layer 9. To avoid “circular reference” conflicts I assigned the outer wing panel and the object that cuts its fixed slats to the common parent — the ”stiff” root rib.

In this source *.blend file you can check all details of the wing presented in this post.

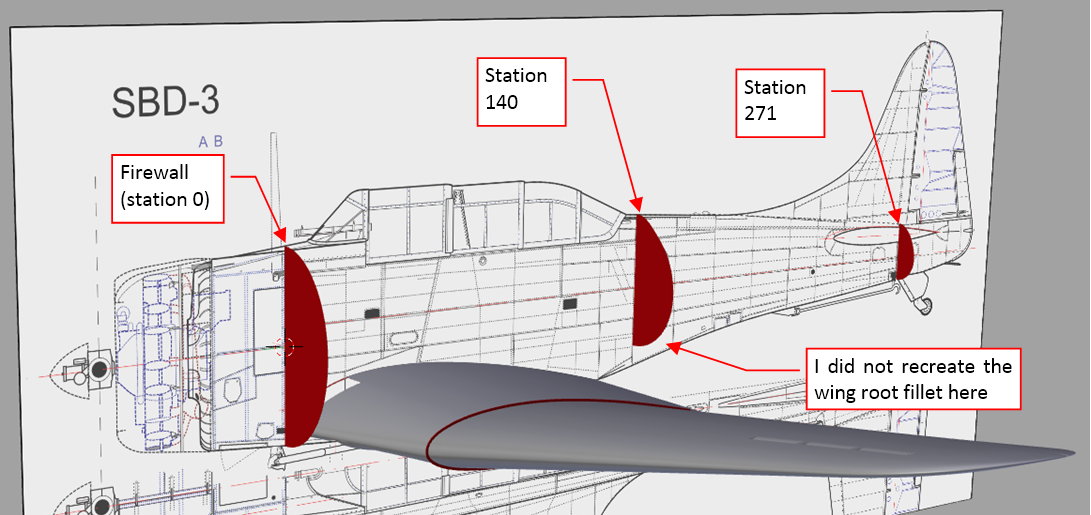

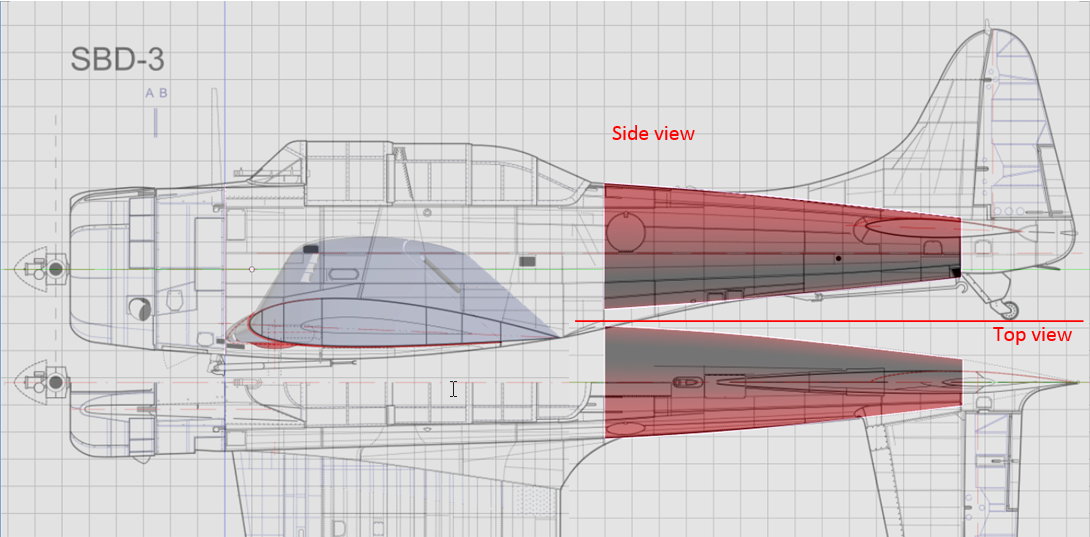

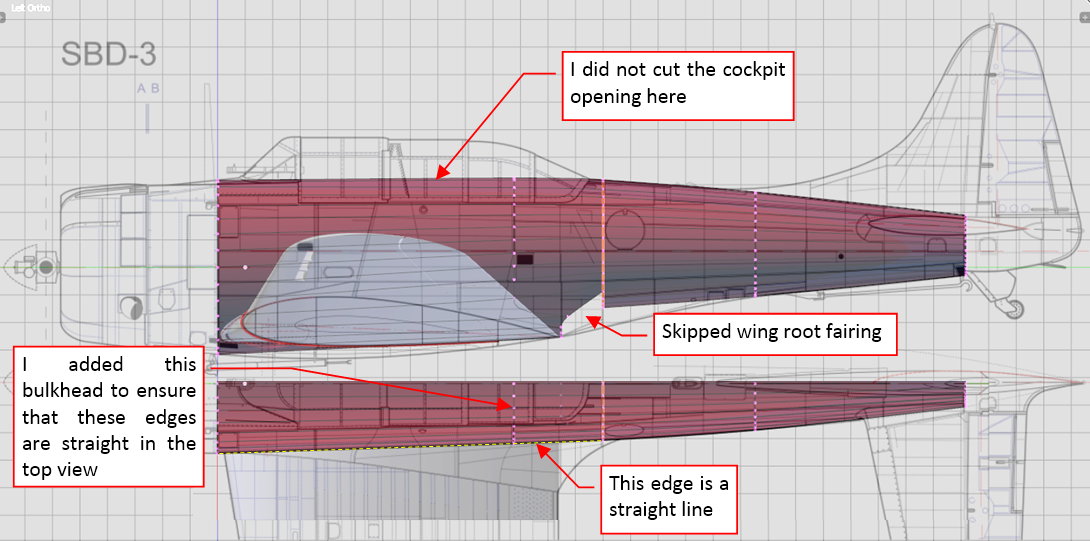

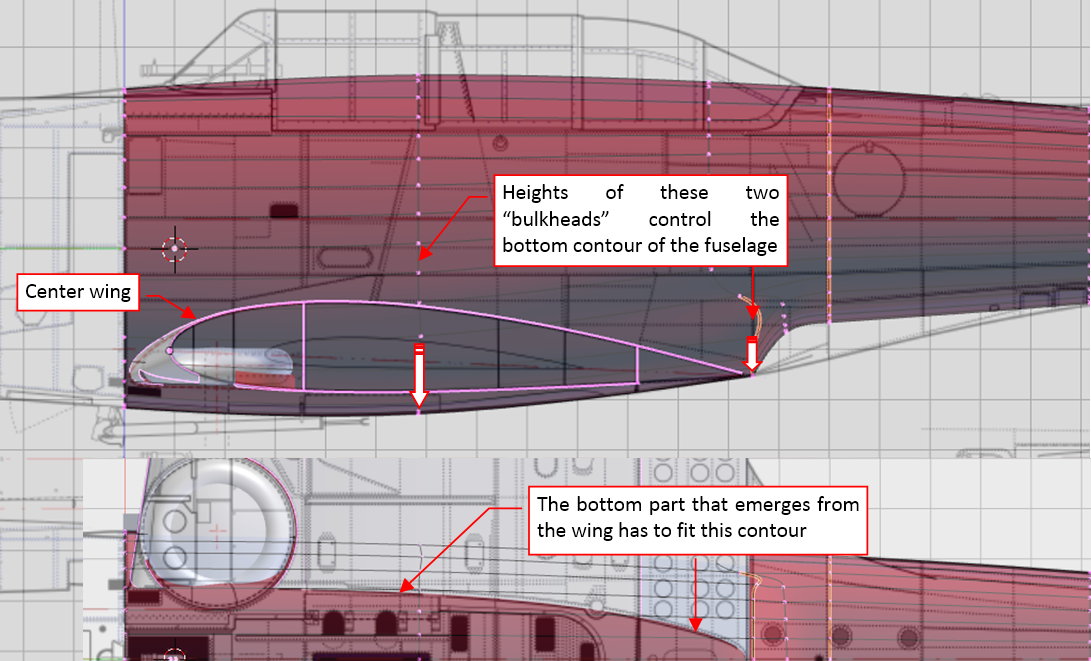

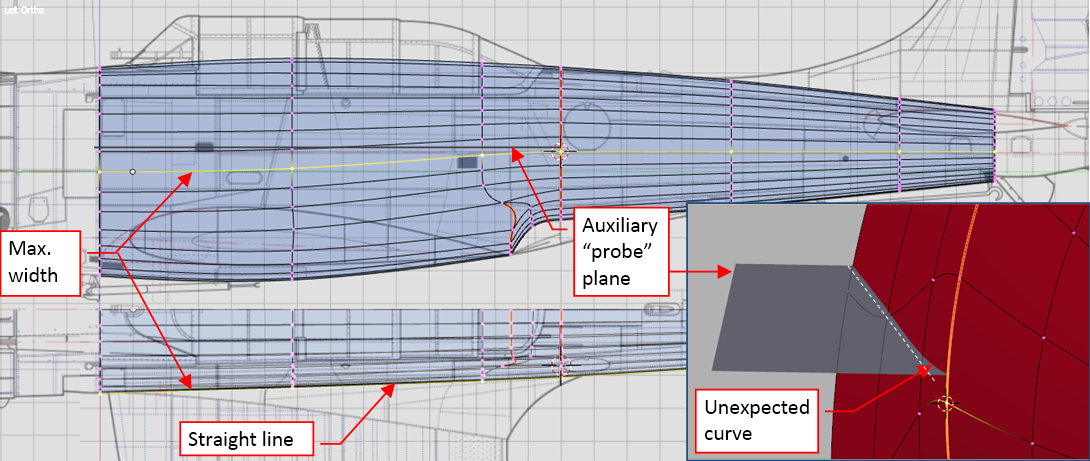

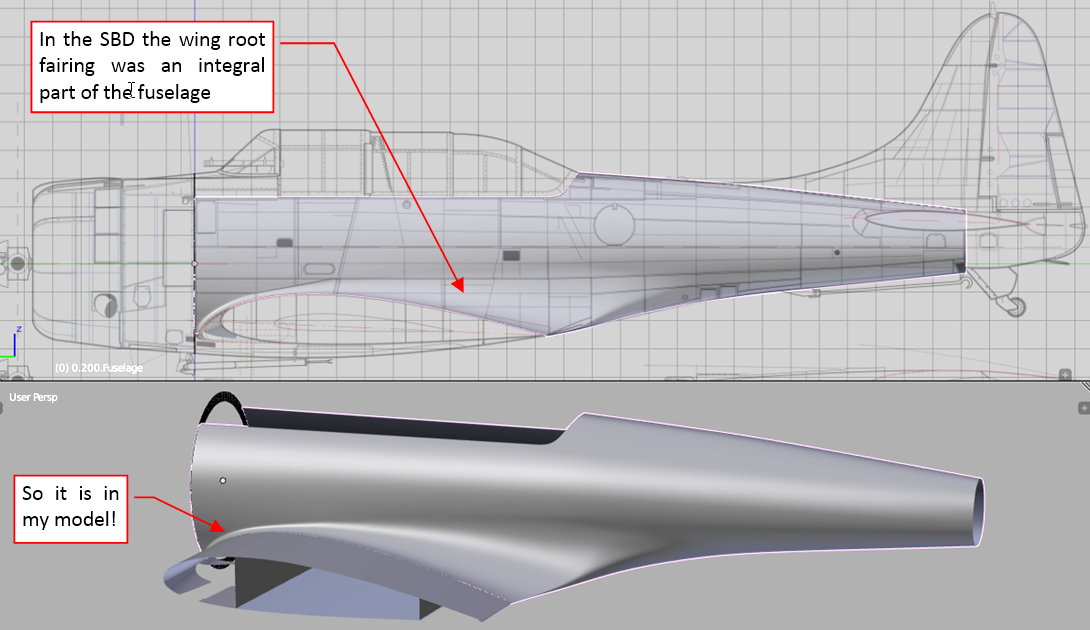

In the next post I will start working on a more difficult part — the fuselage.