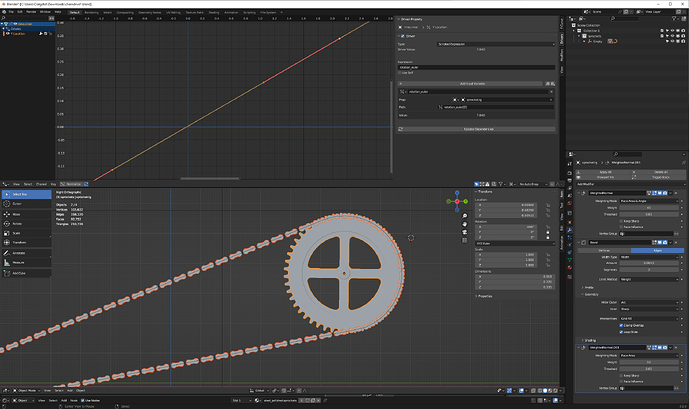

I have a project where I am wanting to model a chain drive, and I’ve had some issues with the drivers, getting the chain to follow the rotation of the gears.

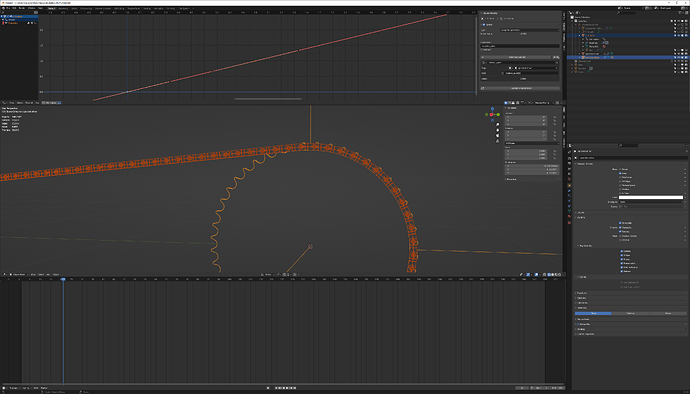

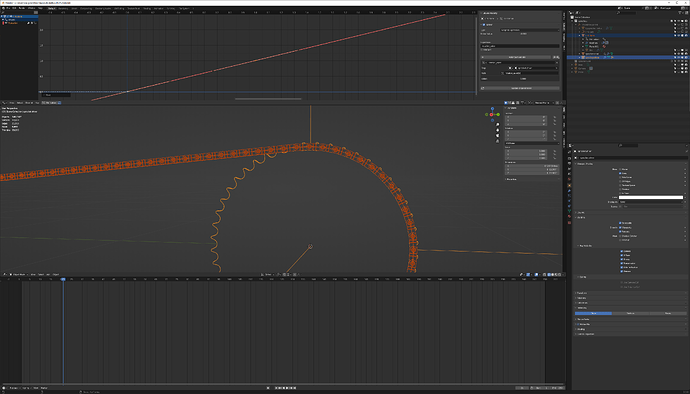

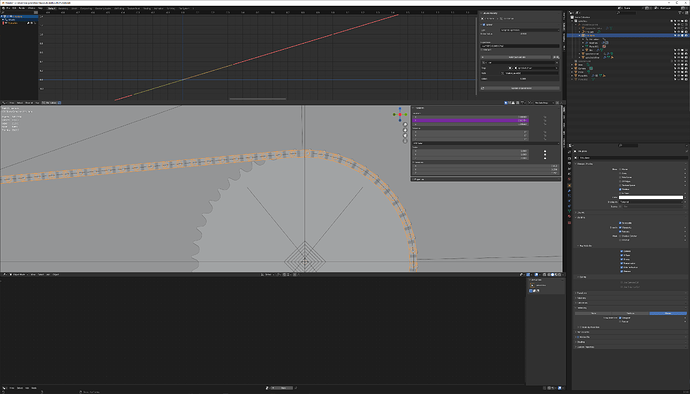

I managed to get the sprocket drivers to work, so that the small gear follows the gear ratio of 3:1, respective to the larger sprocket on the right. I tried copying over the driver from the large sprocket to the chain elements, but it results in a mess when that sprocket is rotated. The links move away and out from the path the chain elements are parented to. I’m not quite sure how to get them to follow the path in sync with the sprockets. I did watch a few tutorials on Youtube, but that didn’t help much as the driver settings they provided were specific for the kind of arrangement they had, and mine is different. Also later I noticed that the small sprocket’s teeth don’t quite match the gaps in the chain, but that should be easy to fix.

What would be the best method to deal with this? Unfortunately, I’m fairly new to using drivers, so I’ve hit a wall here. I’ve included the small .blend file with this chain drive in it.

chaindrive.blend (528.6 KB)