It’s important to understand the difference between CAD NURBS based modelers such as: Fusion 360, MoI3D, Onshape, Solidworks, Catia, Pro-E and Surface Modelers like Blender, Lightwave, Modo, Maya, SketchUp, 3D Max.

CAD is typically thought as an engineering tool. If you look at the computer keyboard you are typing on today, chances are the keys are plastic. To be able to manufacture something with such exacting requirements needs a program that can keep track of very small tolerances, while still being able to create the “constructive solid geometry” that is needed to create a mold for the item all the while calculating offsets to handle things like shrink factors, sprue location, ejector pins, draft angles, and other plastic molding techniques.

These programs can also help create the molds, do stress and heat analysis, create machine paths for metal cutting and so much more. And many of them typically cost so much more as well.

Solids are so much better for working in the real world, and if you had a 3D printer, you’d understand instantly. 3D prints are “watertight and manifold.” This means they’re solid. CAD programs can only create solids, just as you can only create solids in your workshop with wood, nails, glue, etc…

With Blender, it’s easy to create non-solid models. It may be a microscopic hole or a flipped poly or a one sided surface. There are a myriad of ways to build non manifold geometry in surface modelers. Trying to fix it can be very time consuming. I used to use surface modelers for my 3D printing, then switched to Moi (a solid modeler) and all of a sudden things got so very much simpler.

The other thing is surface modelers work with polygons, not NURBS. So, the “atomic” unit of a surface modeler is a face or polygon, which has a “facet” and so it’s not possible to represent exactly a curved surface in a poly modeler. This can come into problem when you’re trying to solve for multiple continuous surfaces, such as where a car fender meets the hood of a car. A very difficult math problem indeed.

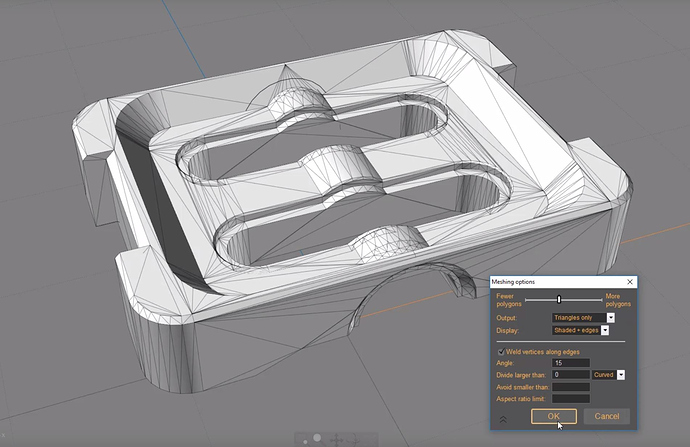

One HUGE downside to CAD and NURBS is the convert to polygons issue. It’s very difficult to create any sort of clean (and human editable) mesh when converting from NURBS. Moi probably has the best converter I’ve ever seen, and it still has problems. The resulting mesh is typically impossible to work with unless you retopo it. Check this CAD to Poly mesh I created years ago to help show the problem.

Even if you don’t put too much weight in poly topology, CAD topology is just horrendous. Perfect poly topology is great if you need to animate/deform a character (think stretchy bounce of an M&M). It provides much less value for Hard Surface models, and in fact, IMO, the Sub-D route is overthought and overused.

I don’t know of any other poly modelers which have the modifier stack like Blender (perhaps Houdini, which I don’t use). Certainly an UNDO history is not what we’re talking about here. NITROX3D is focused on the iterative manipulation of the modifier stack to infinitely tweak proportion and details. That is not possible with UNDO. While it is possible (to an extent) with CAD, there is significant work in setting up such a parametricized workflow.